Reclaimed Refrigerants: Bridging the Gap in the Transition to a Low-GWP Future

This year’s 19% reduction in HFC imports will tighten supply for servicing legacy systems. Reclaimed refrigerants can help bridge the gap — but only if we maximise recovery and reclamation.

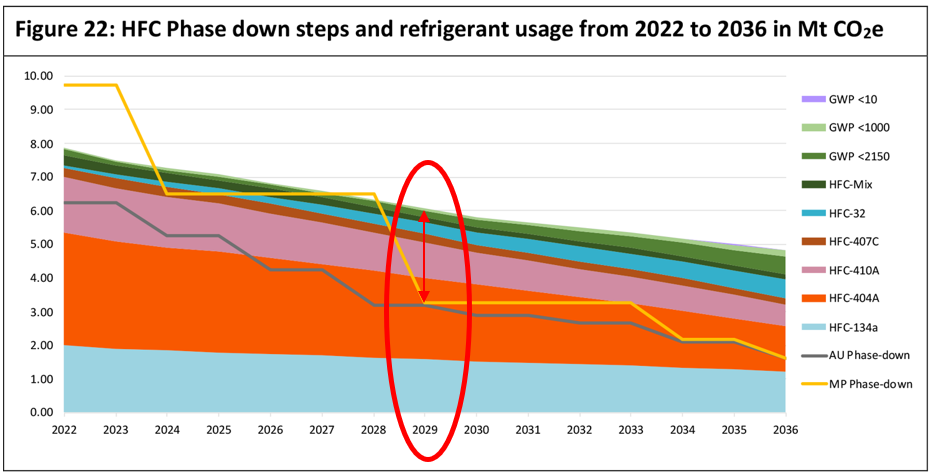

A decade ago, the Kigali Amendment to the Montreal Protocol was signed, with almost 200 countries committing to phase down the production and use of hydrofluorocarbons (HFC). Since Australia began its phasedown schedule in 2018, we’ve already reduced HFC imports by more than 50% of the 2017 baseline CO2e amount. This year marks another major step, with the allowable import volume dropping by another 19%.

Recent industry data* suggests that by 2029, demand is expected to exceed permitted imports by as much as 50%, highlighting a significant supply shortage. That means contractors, equipment owners, and end users may start feeling the pressure.

To help bridge this gap and support the transition to a low-GWP future, reclaimed refrigerants and low-global warming potential (GWP) alternatives – especially Hydrofluoroolefins (HFOs) and HFO/HFC blends – will be increasingly important.

Supports the Transition to Lower GWP Refrigerants

The industry must transition to lower GWP refrigerants, while ensuring that legacy refrigerants are responsibly managed to prevent their release into the atmosphere. Recovering and reclaiming used refrigerants enables businesses to keep their existing equipment running until it reaches end of life. This reduces the need for immediate capital expenditure on equipment that still has significant life remaining, helping businesses save money by avoiding premature replacement.

THE ROLE OF RECLAIMED REFRIGERANTS

Ensures Supply Continuity Amid HFC Phasedowns

In Australia, as well as many countries around the world, HFC phasedown quotas and GWP limits by application are tightening the availability of these refrigerants across all industries. Reclaimed refrigerants play a vital role in supply continuity as virgin product quotas decline, helping businesses maintain essential cooling operations and supply chain resilience.

Increases Circularity of the HVAC-R Industry

Reclaimed refrigerants embrace the circular economy principles – an approach that aims to keep resources in use for as long as possible, extracting maximum value before recovering and repurposing materials at end of life.

By reusing what we already have, rather than sourcing and producing new materials, we reduce the demand for virgin refrigerant production. This minimises the need for raw materials and decreases the energy-intensive manufacturing processes associated with virgin refrigerant production.

RECYCLED VERSUS RECLAIMED REFRIGERANTS

Understanding the difference between recycled and reclaimed refrigerant is crucial, especially in compliance, performance, and quality assurance.

Recycled refrigerant is used refrigerant that is removed from equipment, undergoes basic cleaning and then reused in the same system. There is no set standard for recycled refrigerant quality, which means its performance can vary. Lab analysis to AHRI standards is the only reliable way to verify if recycled refrigerant meets reuse quality and purity requirements.

In contrast, reclaimed refrigerant is used refrigerant that has been recovered and processed through advanced filtering, drying, removal of non-condensable gases, and where required, separation or distillation to return it to virgin-quality specifications (such as AHRI Standard 700). Purity and other quality parameters are then verified using the analytical methods prescribed in the standard to confirm the reclamation process has been successful and the refrigerant is fit for reuse.

Looking Ahead

Reclaimed refrigerants have an important role to play in bridging the gap as we transition to a low-GWP future. By increasing recovery, reclamation and reuse, we can extend equipment lifecycles and reduce our reliance on virgin production. Every person has the power to take action and drive change.

Together, we can build a sustainable future.