A-Gas South Africa launches US Refrigerant Recovery Service

A‑Gas South Africa, a leader in the supply and lifecycle management of speciality chemicals, is taking the lead in preventing the venting of refrigerants into the atmosphere, which not only damages the ozone layer, but contributes to global warming.

The company is achieving this through its association with Rapid Recovery of the US, which it acquired in 2016. A‑Gas South Africa introduced its Rapid Recovery service offering for the local market at a media event held on the 1st and 2nd November at supplier Metraclark in Cape Town and Johannesburg respectively.

The event was attended by Rapid Recovery US Managing Director, Adam Dykstra. The company is not only the largest refrigerant recovery company in the US, but in the world.

“We recover more refrigerant than any other single company globally,” Dykstra reveals, “Anywhere there is a regulatory compliance for a contractor, or a demand for such compliance from a customer, there is a need for high-speed refrigerant recovery solutions.” He adds that the recovery equipment available to contractors today is off-the-shelf and bulky.

“We offer a service that essentially encompasses both a technical compliance and legal solution. We not only assist contractors in complying with the law, but also give their own customers peace of mind that they are dealing with professionals well-versed in the latest technology and trends,” Dykstra explains.

One of these latest trends is the A‑Gas Rapid Recovery service, which offers contractors the latest equipment.

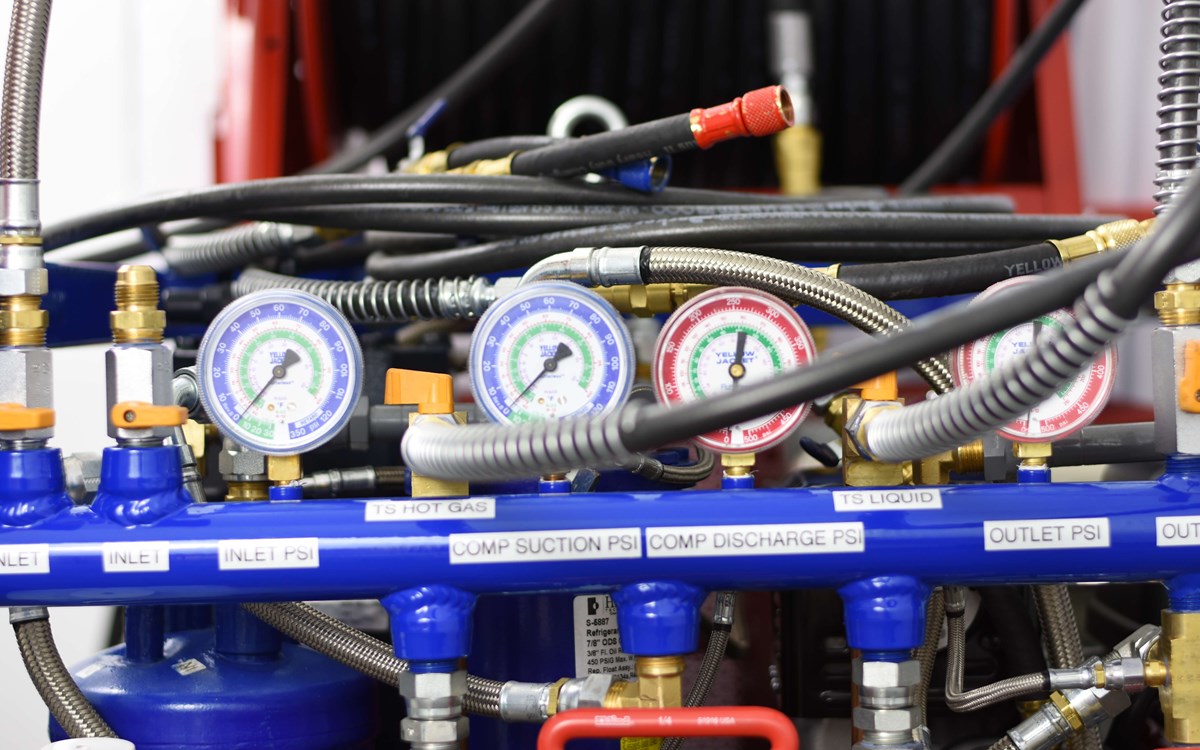

“Our machines are based on the simple concept of a compressor and a condenser,” comments Dykstra, “It basically recovers refrigerant from one unit to another really fast, in order to prevent it from venting to the atmosphere.”

“SANS 10147 regulations have specific refrigerant recovery, tracking, handling and documentation requirements. A‑Gas Rapid Recovery provides all necessary documentation electronically to clients,” A‑Gas South Africa National Sales Manager, Michael Labacher, explains, “Rapid Recovery is performed by us, while the contractor team can utilise its specialised skills to diagnose and repair the equipment, rather than handling empty and full recovery cylinders, and waiting on traditional recovery equipment. Custom-made petrol-operated machines are typically ten times faster than a contractor’s ‘buzz box’ (recovery machine).”

Dykstra cautions that venting occurs when a line to a machine is simply cut, or it develops a leak, allowing the refrigerant to escape into the atmosphere, “The correct thing to do is to capture that refrigerant, keep it from damaging the ozone layer and also from causing global warming, clean it, and bring it back onto the market.”

“The A-Gas Rapid Recovery solution stops that one-way train from refrigerant coming in and going straight to the atmosphere through a piece of equipment that is not properly maintained or inefficient,” Dykstra elaborates, “By recapturing it and bringing it back onto the market, we also reduce the quantity of new refrigerant that needs to be produced, thereby lowering the global footprint.”

Dykstra highlights that A-Gas Rapid Recovery launched in the UK and Europe earlier this year, and will launch in Australia in 2018, as part of its overall globalisation strategy. “South Africa is now compatible with the US as far as refrigerant recovery speed is concerned. The playing field has definitely been levelled here with the advent of the A-Gas South Africa Rapid Recovery service.”

Dykstra stresses that extensive technical support is provided to all Rapid Recovery technicians, who receive four-weeks’ local training, which includes legal and technical aspects. The A-Gas Rapid Recovery service is applicable to the heating, ventilation, air conditioning, refrigeration, demolition and marine industries.